I agree with the others. It's all about the range and the specifics of the site, not just an absolute number.

The 'Critical Rail Temperature' is the temperature at which any particular rail gets to a point where the risk of a buckle become 'intolerable' in a risk manegement sense. This does not mean it will buckle - far from it, but just means it's the point we start taking additional precautions.

For new track, the ballast wont be consolidated, no matter how good the wackers and tampers etc were, and it needs to be quite literally shaken down under traffic for full consolidation to be acheived (or something like a Dynamic Track Stabiliser to be used, which speeds things up significantly but brings its own set of issues).

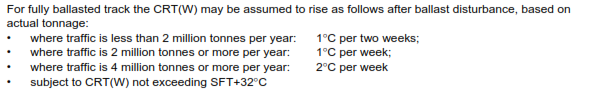

Track gets better at this rate (extract from NR/L2/TRK/001mod014):

There are 4 values we use for CWR:

1) SFT - 'Stress Free Temperature' - The temperature at which, if the CWR rail was cut, it would neither expand nor contract. If works are done overnight and stressing has not been done, this can be very low.

2) CRT(W) - 'Critical Rail Temperature' (see above) where we start taking action. A 'watchman' is usually deployed to site. It's their job to keep a close eye on actual site specific temperatures, monitor the track for any signs of a buckle becoming more likely, and stop traffic if the track becomes unsafe, plus implement and withdraw the higher level measures as tenmperatures rise and fall.

2) CRT(30/60) - A temporary speed restriction of 30/60 is imposed.

3) CRT(20) - A TSR of 20 is imposed.

Different calculations are done depending on the SFT of the rail and the reasons for the problem. A new track where the last ballast train was cancelled in order to avoid a possession over-run will be quite weak, so will have a low SFT.

Here's a hypotetical situation (I know nothing of what's going on Plymouth BTW so this may be nothing like the reasons there):

Track re-laid but things go wrong and possession heavily delayed. Stressing and last ballast train cancelled and thus top ballast quite low and track not fully consolidated, plus low SFT.

SFT= 5degC.

CRT(W)=SFT+15=20degC.

CRT(30/60)=CRT(W)+3=23degC

CRT(20)=CRT(30/60)+5=28degC.

So, it's quite conceivable that a 20mph TSR could be in placed during times when the rail temperature is higher than 28degC, which is warm weather and direct sunlight could be an air temp of only 15-18degC. Hence the current delays.

If the track is not welded up then instead we calculate something called the 'joint closure temperature', which is where all the gaps we've left for expansion close up and the risk of a buckle goes up remarkably, but again, this is subject to a similar calcualtion of CRT values and will result in the same 30/60 or 20mph TSRs.

HTH!

) first.

) first.