"Single Rail" Track Circuits

View attachment 180746

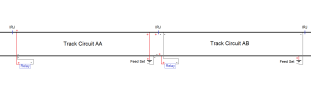

In the above diagram, I am showing two track circuits. The rails of the track are shown as thicker black coloured lines. The bottom rail has no Insulated Rail Joints (IRJ or IBJ). The top rail is shown with three IRJs, each shown as a vertical blue colour line.

Below the bottom rail, I have shown symbols for a cell (battery) to represent the track circuit feed sets. And also shown symbols for the track circuit relays.

I have shown the interconnecting cables in thin red coloured lines for the cables (wires) carrying the positive polarity current. And in a dark grey colour for the interconnecting cables carrying the negative polarity current.

I have also added + (for positive) and - (for negative) symbols at various places to again indicate the polarity.

Please note that as there are no intended electrical connections to earth (ground), each feed set electrically is independent to any other.

With no trains present, for track circuit AA, the positive polarity current flows from the feed set shown in the middle to the top rail, then along it to the left, then down to the positive connection on the relay. The negative current flows from the negative connection on the relay along the bottom rail back to the negative of the feed set. As a result, the relay is energised (or "up").

The same happens for the adjacent track circuit, here called AB, except that now the top rail is negative and the bottom rail is positive.

On the top rail, the left hand IRJ stops track circuit AA from affecting or being affected by anything (including trains) to the left of the IRJ. The middle IRJ stops track circuit AA from affecting or being affected by track circuit AB or from trains to the right of this IRJ. Similarly, track circuit AB is not affected by track circuit AA or any trains to the left of the middle IRJ. It's similar again for the right hand IRJ.

So, you may at this point have a question. Something along the lines of "but on the bottom rail, in the middle you show both positive and negative symbols next to one another, how can that be correct without there being an IRJ to keep them separated?"

Ahh, well, this is where you have to remember that each feed set is electrically independent from one another. The polarity shown is relative to that of the feed set ONLY. So in the real world, the whole length of the bottom rail is negative for track circuit AA (feed set and relay) no matter where you are. But for track circuit AB (feed set and relay), the whole length of the bottom rail is positive.

Now when a train moves on to track circuit AA, the wheels and axle of each wheel set will short the top rail to the bottom rail. This results in an alternative route for the electrical current from the feed set for AA track circuit. As a result, very little or no current gets to the relay for this track circuit, so relay AA de-energises (drops). Note that this has absolutely no effect on track circuit AB.