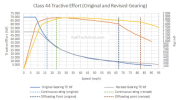

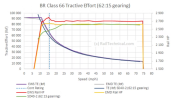

As an illustration, the TE versus speed graph for a class 66 (from

Steve Brown's Rail Technical website) - with a US SD40-2 for comparison:

The 'maximum starting TE' is basically a function of axle weight and rail head condition (potentially with sanding) - the 'adhesion' - combined with the maximum allowable current through the motors (the current generates the axle torque) and how good the wheelslip control is at exploiting the available adhesion. But limitations of the DC motors and the other electrical equipment mean that it can't be sustained without damage for long periods of time. AFAIK EMD specify a 'minimum continuous speed' below which operation at very high tractive effort is time-limited. The vertical blue dotted line marks the 'continuous rating' speed.

Modern AC motor traction drives don't have the same limitations at low speeds, so can safely generate very high tractive efforts for long periods of time - meaning if you don't care how slowly you climb long gradients you can haul more weight per loco.

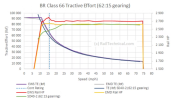

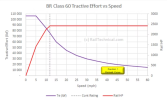

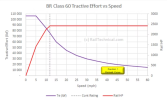

For comparison,

this is for a class 60 (note the lower 'continuous rating' speed and higher starting TE, due to lower gearing and better wheelslip control):

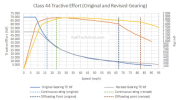

Meanwhile, back in history, this is a set of curves for a class 44, both original and revised gearing (the whole cl. 44/45/46 set are here -

https://www.railtechnical.com/class-44-45-46-diesel-electric ):